The largest photovoltaic facility in the world installed on the rooftops of a factory began operating in September 2008.

An area of 320,000 m2, similar to 42 football fields, was covered with 84,848 panels with a photovoltaic capture area of 189,000 m2. The panels generate energy equivalent to the consumption of 4,600 households. The investment cost was €61 million.

After the loss at the facility, the analysis of the cause and the extensive experience of the professionals from RTS International Loss Adjusters determined the efficient cause of the loss in order to claim from the party responsible for it.

About the loss

On 24 January 2009, just four months after the facility began operating, there was an atypical cyclonic storm that resulted in thousands of losses throughout Spain, especially in industrial buildings, facilities and infrastructures.

In this case, the effects of the wind caused the anchoring of the panels to the roof to fail, thus causing considerable damage to the panels, their electrical connectors and the trunking through which the electrical cables run. This left the photovoltaic facility in an extremely bad condition. The claim for the damage and associated business interruption under the meteorological phenomena (wind) cover came to several million euros.

The system for mounting the panels on the roof

The facility is formed by thin-film photovoltaic cells on a rubber base spread over the roof.

The special characteristics of the flexible panel used for this installation meant that no support structure was required to fasten the solar panels to the roof. A Velcro® anchoring system was used.

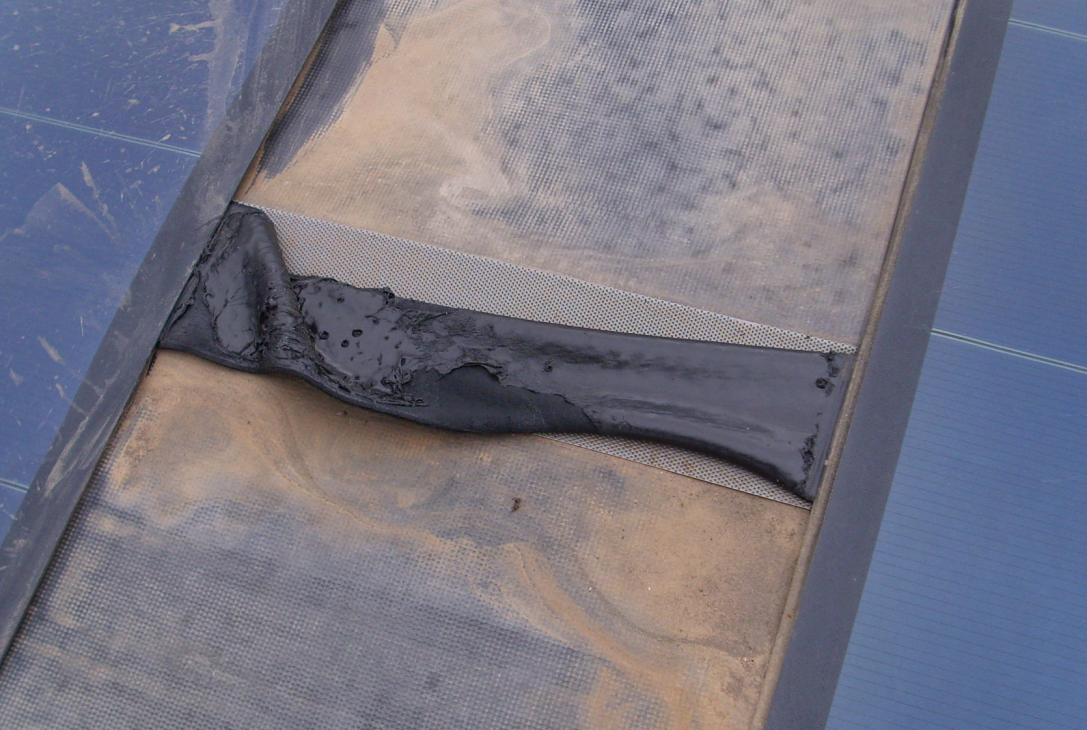

The Velcro® sheet adhered to the panel was joined with Velcro® strips distributed on the roof. The size of the strips was calculated in accordance with the CTE (Technical Building Code) to withstand the action of environmental agents (snow load and wind load).

The Velcro® was attached to the panels and also to the roof by applying adhesive onsite during assembly after first applying a primer, whose function was to clean the adhesion surface and strengthen the adhesive properties.

Analysis of the cause by RTS International Loss Adjusters

The action of the strong wind recorded was first considered to be the cause of the loss since this facility is exposed to the elements and has to withstand major meteorological forces in a geographical location that is highly prone to intense winds. However, RTS International Loss Adjusters asked the insured for the facility’s detailed design and after careful reading of the structural calculations, found the following:

DETERMINING METEOROLOGICAL LOADS

Wind load

According to the drawings attached to the above-mentioned basic document, the buildings where the photovoltaic facility was to be assembled are in a type B wind action area and, therefore, considering a wind speed of 97.2 km/h would suffice. However, to take into account the area’s special conditions, a wind speed of 160 km/h was considered for the calculation. The wind would have a suction action and reach a value of 129.1 daN/m2.

Therefore, placing seven Velcro® strips with a width of 152.4 mm longitudinally to the panel would ensure they were fastened.

However, as RTS discovered during our inspection of the roofs, the panels were only placed on five Velcro® strips with a width of 100 mm; therefore, we can conclude that they did not meet the design conditions as the Velcro® contact area with the roof was considerably reduced.

To determine whether this was a design error, the fastening system used in the photovoltaic facility on the roofs was tested at INTA (Spanish Institute of Aerospace Technology) and it was found that it complied with the Basic Document of Structural Safety, Actions in Building (SE-AE) of Royal Decree 314/2006 dated 17 March; therefore, we had to rule out a design error and the use of an insufficient number of Velcro® strips as a cause of the loss.

Also worth noting is that most of the panels had been pulled away where the Velcro® is attached to the panel, in other words, the wind’s dynamic pressure had exceeded the adhesive’s adhesion capacity.

To determine the failure mechanism of the panel anchoring in the photovoltaic facility, RTS INTERNATIONAL LOSS ADJUSTERS requested a study in an accredited laboratory. It was concluded that the panel anchoring failed due to an assembly fault during installation, namely a lack of primer on the panel base involved in the attachment.

This meant the adhesive used on the surface of the panel base to attach the panels to the roof did not adhere properly and, consequently, the attachments lacked resistant properties.

In the tests in the INTA wind tunnel we requested on two samples, one applying a primer to the attachment and the other without applying the primer, it was found that the fastenings only failed in the sample without the primer.

The panel supplier’s installation manual, which was given to the main contractor responsible for the assembly of the panels, state that the primer must be used.

Differential advantage gained from the involvement of RTS International Loss Adjusters

The property damage to the photovoltaic facility occurred on a day when there was a major atypical cyclonic storm, which led to many similar losses in photovoltaic facilities. For that reason, the loss could easily have been classified as ‘property damage caused by the wind and covered by the issued policy’. Under this hypothesis, the insurance company would have had to pay a settlement for the loss amounting to several million euros.

The involvement of RTS International Loss Adjusters determined the efficient or primary cause that led to the claimed damage. This not only made it possible to redirect the claim to the party that actually caused it, since the damage was a consequence of an assembly error and not the action of the wind, but also to detect a systematic execution error, which, as no one was aware of it, would have been a hidden defect needing correction and excluded by any property damage policy. This is exactly what you would expect from good loss adjusting.

The investigation conclusions were shared with the insured and policy broker, thus enabling a claim to be made against the main contractor of the work as the facility was under warranty. Since the contractor paid the cost of rectifying the error, all the intervening parties—insurance company, broker and insured—were satisfied with the involvement of RTS International Loss Adjusters.

About Fernando Pérez

Fernando is an industrial engineering technician who graduated from the University of Zaragoza, Spain. He is an insurance loss adjuster recognised by APCAS, INESE and UNESPA and is also a FUEDI-NLAE and FUEDI-ELAE.

Besides being one of the general managers in the RTS Group, his CV includes over 22 years as a loss adjuster.

He specialises in claims management and adjusting industrial losses, primarily renewables in the technical and energy sectors. In the engineering field, he has been involved in several projects and the technical management of industrial facilities.

About RTS International Loss Adjusters

We are an international business group founded in 1989 with our own offices in Spain, Latin America and Portugal. Since our beginnings, our business has focused on adjusting losses in industrial risks and all types of technical sectors.

For more information, please visit our website http://rtsgrupo.com/